From the speech “The evolution of the distribution network”

SMART GRID DAYS 2024, 18 — 19 September 2024.

Centria is a city distributor that operates in 16 mainly Tuscan provinces (Italy), but with some excursions to Puglia and Umbria, and has collaborations with other companies in the Grosseto area (Lazio region). It has about 6,000 km of gas pipelines, managed mainly at medium and low pressure, and more than 400,000 customers.

Centria has always wondered if it is possible to make a contribution to decarbonization. Today, cathodic protection also asks itself this question. The distributor would like to make his work more efficient and advanced, despite offering an energy-intensive service.

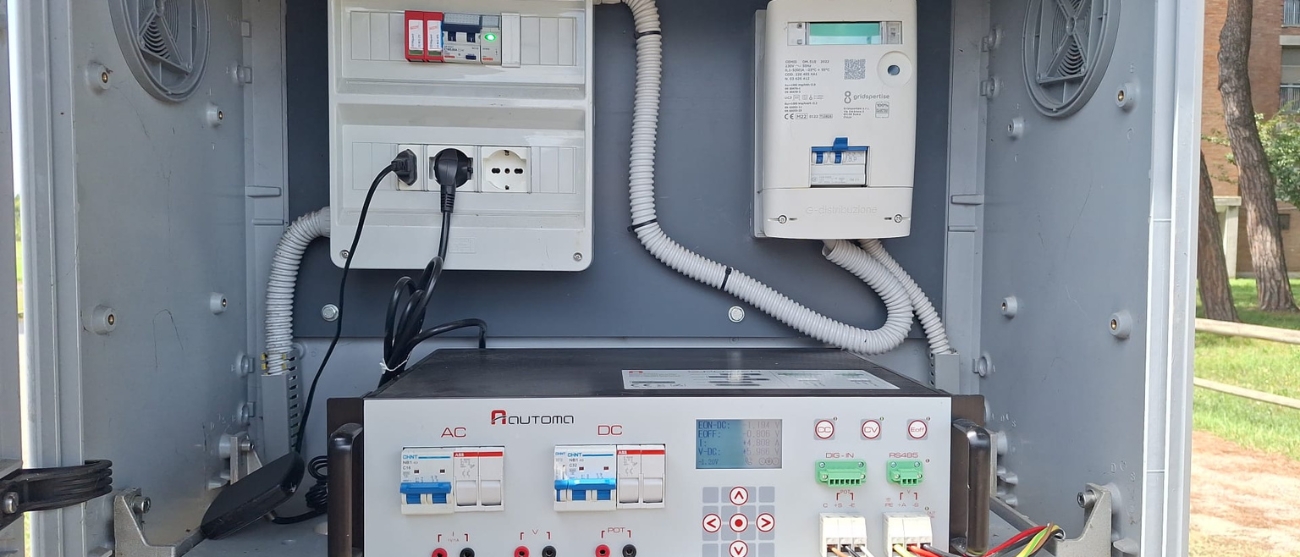

In this case, technology comes to the aid: the case studies thatwe present are two examples of interventions carried out on the cathodic protection of two city distribution systems using impressed current. In both cases, an AUTOMA G-POWER device was installed to replace the rectifier previously in operation: in the first case, G-POWER replaced the only rectifier in the system, while in the second it replaced one of the two rectifiers.

Case 1: The starting situation and the AUTOMA solution

The system is located in the town of Montale, in the province of Pistoia. It is equipped with 13 km of pipes, of which about 50% medium pressure and 50% low pressure, and a single cathodic protection rectifier, operating at constant potential, with base current.

The adjustment was made with the Eon potential because it was the only way that that rectifier could work, that is, with a potential of -2.8 V corresponding to about an Eoff of -1.1 V. The base current was 1.30 A that had to be constantly supplied even in conditions of potential lower than that required. The current supplied varied a lot because it is a very interfered system. The variation ranged from 7 A to 12 A, with an average value of about 10.5 A.

The kilometer extension of the system is quite large, so you start from a fairly flat area and arrive at the first hills. As can be seen from the first image, the pipes are fairly distributed. While in the second image you can see the dislocations of the characteristic and remotely monitored measurement points.

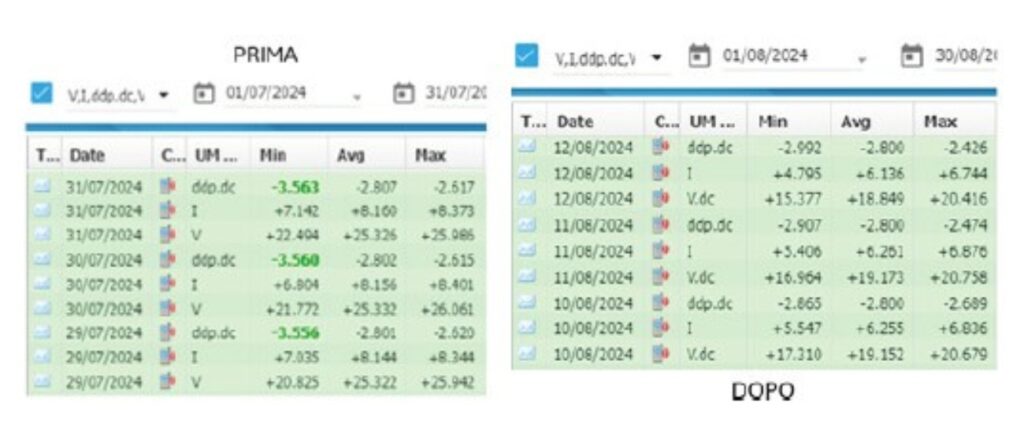

From the remote control data before replacing the rectifier, you can actually see that the current has values between 7 and 12 A, with an average value around 10 A.

We removed the rectifier that was previously in operation and replaced it with AUTOMA’s G-POWER. After turning it on, we reset the parameters that were used with the previous rectifier, namely constant potential regulation with an Eon value of -2.8 V. We chose to use G-POWER with the same setting as the previous rectifier to check if there were any operating differences under the same conditions. In the table you can see the new data returned.

So we haven’t changed either the adjustment system or the system or its surrounding elements. Right from the first ignition we had a fairly unexpected surprise: the current was reduced by almost 25%, going from an average value of 8 A to just over 6 A.

We asked ourselves why and with AUTOMA we did a bit of analysis on these measures. Let me start by saying that the amount of time we had for analysis was short: the rectifiers were put into operation in the month of July-August 2024, and what you see are preliminary data about two months after the start of the system, in September 2024. But these checks give us hope that we have at least taken the right path.

Why was there this reduction in power? Going to see the measurements, we noticed that the only thing that has really changed in the data coming from the remote control is the average square deviation from the adjusted value. The difference is important: we went from 0.2 to 0.02. This variation indicates that the regulation is much more stable over time, which translates into a smaller variation in the current supplied and therefore in a more stable and lower current than it was initially.

Case 2: The starting situation and the AUTOMA solution

The second system we are talking about is in the town of Sesto Fiorentino (Florence), where Centria has two rectifiers. Of these, only one was replaced during this test because we wanted to see the interaction of G-POWER with other rectifiers.

Both starting rectifiers operated at constant potential and were both adjusted to -2 V of Eon potential, corresponding to about -1.1 V of Eoff potential. The total current was 13 A, divided more or less equally on the two rectifiers.

We have about 11 km of mainly medium-pressure network, so we had networks in the fourth species and networks in the sixth species (0.5 bar and 5 bar) in the city center of Sesto Fiorentino, which is a very interfered area with the presence of a railway.

Only the rectifier that has been replaced has been set to make the adjustment work on the Eoff potential. We did several tests and then decided to adjust the Eoff potential no longer to -1.1 V (as it was set on previous rectifiers) but to -0.95 V.

At this point, the second rectifier was turned off because G-POWER was more than enough to protect the entire connected structure. First, the two rectifiers shared the current load (about 6 A/6.5 A each), but with the introduction of AUTOMA’s G-POWER one of the two was completely stopped, while the other supplied about half of the current that was previously supplied in total by two rectifiers.

The reduction in current in this case was significant, by 50%, both for the adjustment stability of the rectifier and for the lowering of the Eoff potential. Achieving these results is an important goal for a company with environmental certification.

Let’s mention the ease of installation of the AUTOMA device. G-POWER has also incorporated the data logger, and therefore all its functions: cyclic switch, remote controls, transmission system. It is enough to bring it on site and attach some cables to make it immediately operational, while for the previous rectifiers it was necessary to do a wiring that perhaps in some cases required half a day to connect all the devices. Even a quick installation translates into better efficiency for the company.

In conclusion, with AUTOMA’s G-POWER we have a product that has better regulation and stability in its operation, which is certainly also due to the fact that it has very new electronics. Clearly, being a new product, its potential is still to be explored. But for the moment we can say that, in addition to a significant simplicity of installation, it also offers a great advantage in the possibility of adjusting on the local Eoff potential.

AUTOMA designs and produces innovative and Made in Italy hardware and software solutions for remote monitoring and control in the Oil, Gas and Water fields.

We were founded in 1987 in Italy, and today more than 50,000 Automa devices are installed in more than 40 countries around the world.

Do you want to know the cathodic protection advantages you could have with the AUTOMA monitoring system?

Contact our team without obligation and we’ll tell you what we can do to optimize your infrastructure control.

Head of Cathodic Protection and Electrical Systems Management and Development for Centria Srl (a company of the Estra SpA Group)

Leonardo Ferri is a cathodic protection technician involved in the management of cathodic protection for companies in the Estra SpA Group (both subsidiaries and directly controlled companies), designer of new cathodic protection systems, research and development of new plant solutions, commissioning and supervision of cathodic protection systems.