Biogas upgrading to biomethane is a technological process that converts biogas produced from renewable sources, such as livestock manure or agricultural biomass, into biomethane, suitable for injection into the natural gas distribution network.

It is a complex purification process, which aims to increase the quality of biogas by removing impurities and CO₂ present in it. The resulting methane is then collected, compressed and called biomethane.

The biomethane generated through the upgrading process is chemically comparable to natural gas and can be injected into existing infrastructure and used in conjunction with other sources to meet energy demand.

At present, biogas production and its conversion into biomethane are still much lower than the injection capacity of the NTS offtakes.

Furthermore, this quantity varies depending on the circumstances characterising both the production and conversion processes.

Currently, the gas distribution manager is required to guarantee priority injection to the biomethane producer. Therefore, the system must always feed biomethane into the network when it has biomethane suitable for injection, which has priority over other natural gas plants connected to the same network.

However, there are different scenarios that can occur during the injection process. What can happen?

Possible scenarios during biomethane injection

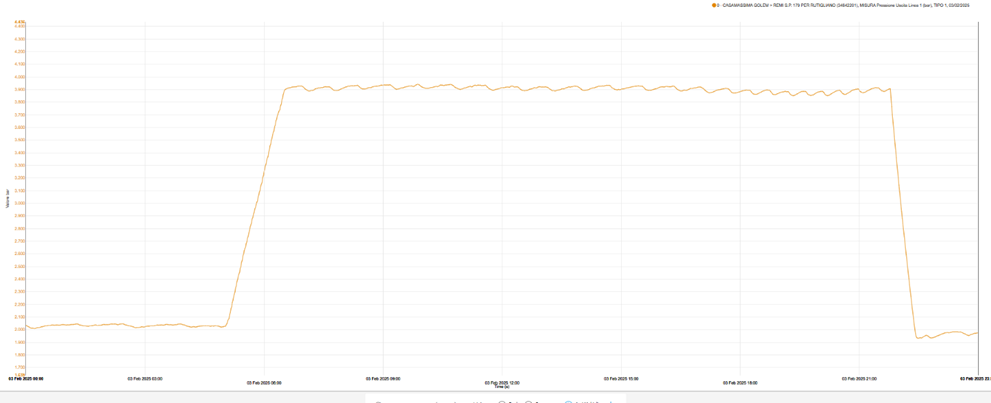

When biogas is produced and the upgrading plant maintains a regular supply of biomethane in both quantity and quality, ideally there are no obstacles to the normal operation of the injection system.

But situations can also arise that lead to critical issues, such as:

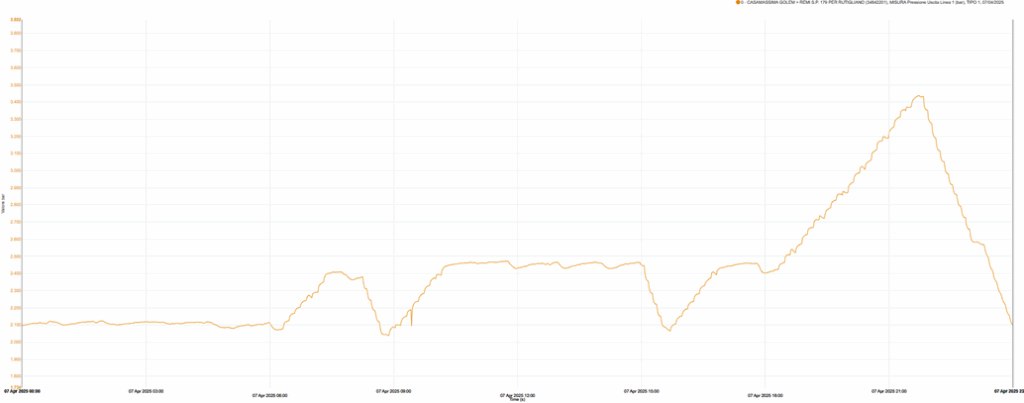

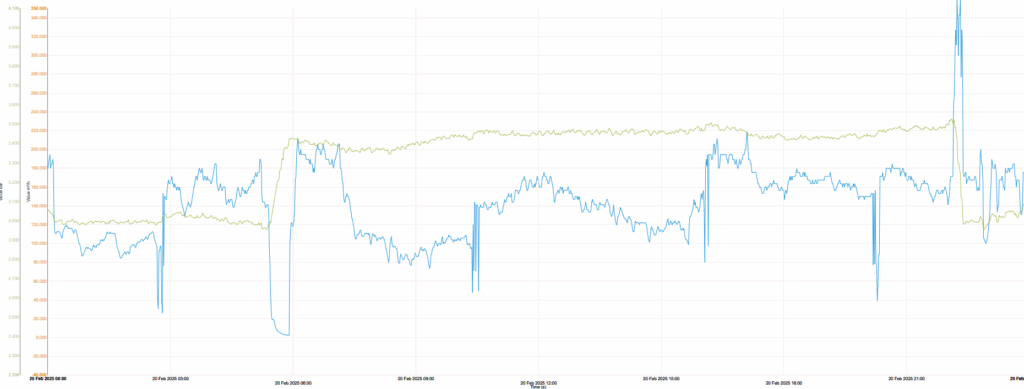

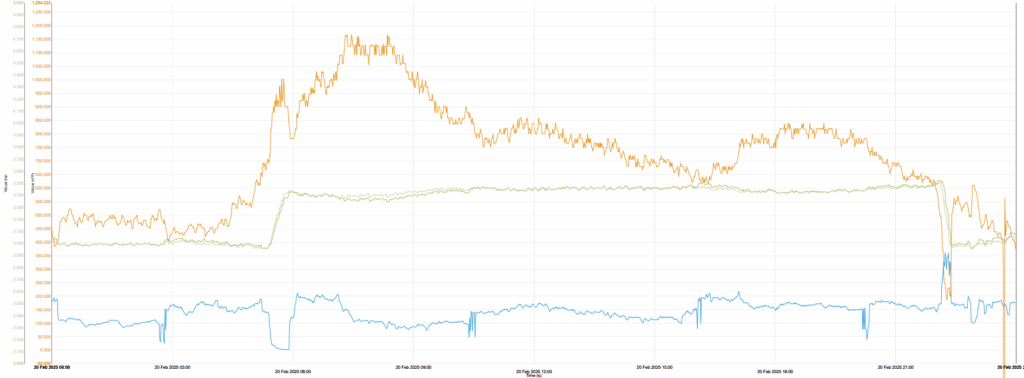

- The pressure measured at the regulator inlet tends to increase progressively due to the increase in biomethane production in the upgrading system. In this case, the risk is that an overpressure phenomenon may occur.

- The flow rate of the upgrading system is higher than the maximum permissible flow rate of biomethane, meaning the producer injects more biomethane than contractually agreed with the gas distributor. This condition does not normally entail risks for the safety of the system but has economic consequences for the producer who incurs sanctions or penalties provided for in the contract for exceeding the emission limits.

- The biomethane coming from the upgrading system does not have sufficient pressure to exceed the network pressure, which in this case is high due to low demand or a backpressure condition. Even if production is regular, network pressure hinders injection, leading to possible system shutdown.

- The network pressure undergoes a temporary increase due to the decrease in consumption. Under these conditions, the network pressure could reach the regulator setpoint, thus causing the injection to block.

- The biomethane coming from the upgrading system does not meet the required quality parameters.There is therefore a problem at the systems/equipment level (safety alarms, prevention alarms, faults, power outages) which forces the plant to stop.

The AUTOMA solution to overcome critical scenarios

To avoid the problems associated with the critical scenarios we have just seen, at AUTOMA we have designed and built a system capable of

optimising the injection of biomethane into the natural gas network and guaranteeing priority injection to the producer, regardless of hourly fluctuations in production, flow rate, pressure and network demand.

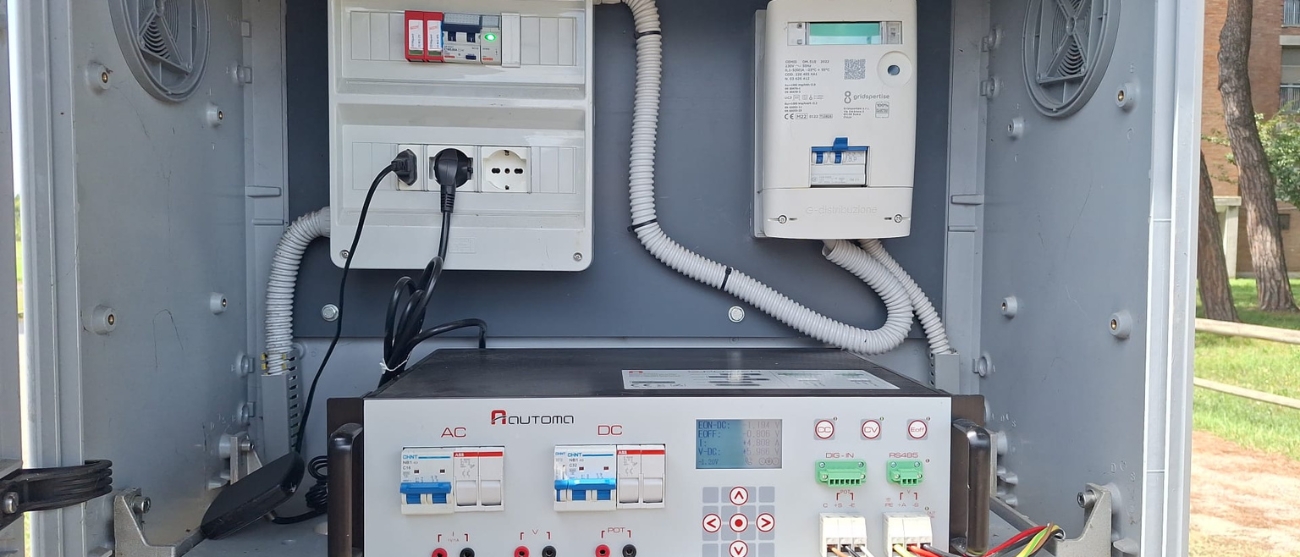

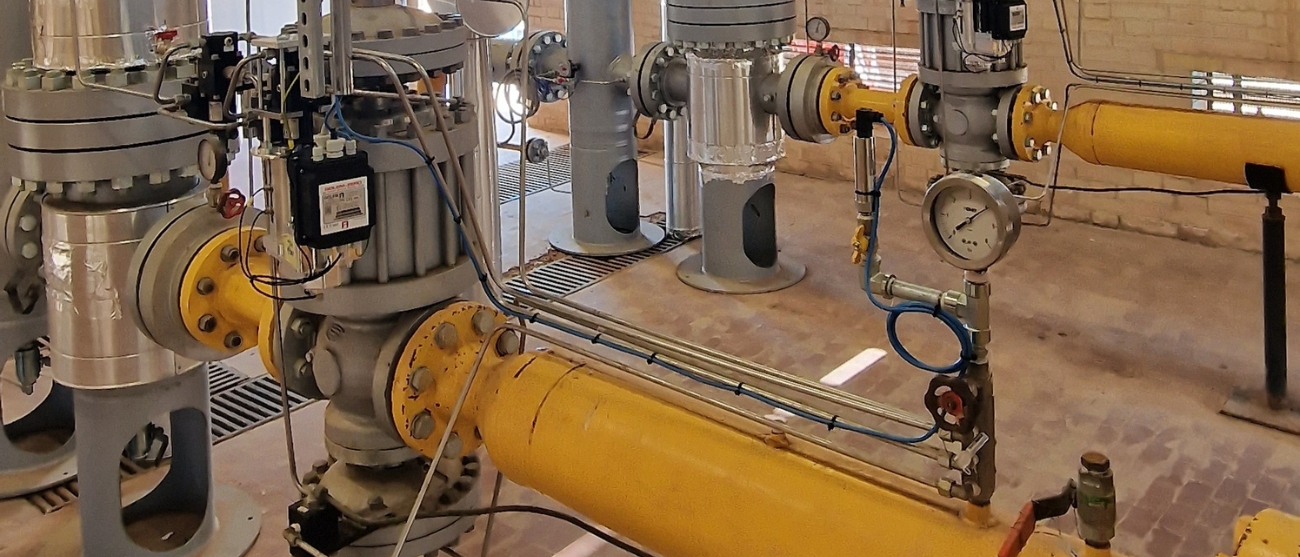

This is the GOLEM-ZERO dynamic regulation system, which combines advanced electronics with an electromechanical actuator. GOLEM-ZERO moves the adjustment screw of a standard pneumatic pressure regulator, transforming it into an intelligent regulator.

GOLEM technology is based on a mechanically coupled servomechanism that interacts directly with the pressure regulator pilots, supported by an advanced electronic system. Thanks to the intelligence built into the system, GOLEM-ZERO can operate in autonomous mode and dynamically adjust based on actual boundary conditions, thus reducing the need for manual intervention on site.The system is applicable to any regulator model and can be easily integrated into existing NTS offtakes, thanks to custom-designed adapters.

Power can be supplied via the electricity network, but also via a photovoltaic system. In addition to the safety controls implemented at the logic level, during the development phase — both in the laboratory and in the field — mechanical and electromechanical safety systems were introduced to prevent issues caused by possible jamming of the pilot adjustment screw and, more generally, with the implemented control logics.

The system can be operated manually or remotely via any SCADA software or through WebPressure (a suite developed by AUTOMA specifically for the sector). It operates in fully automatic mode, dynamically adjusting the regulator set-point according to predefined control logics. The GOLEM-ZERO system communicates locally with the GOLIAH5P (G5P), i.e. an AUTOMA RTU, or with any PLC/RTU via Modbus protocol on RS485 port.

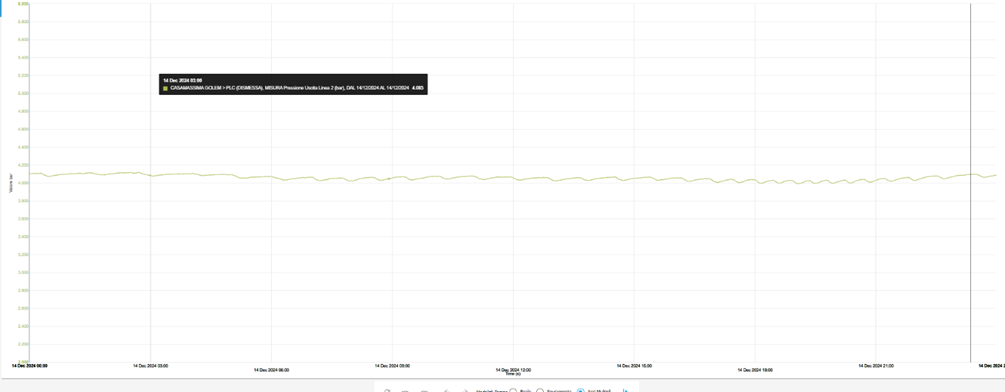

Thanks to GOLEM-ZERO, biomethane injection management takes place in real time, remotely and automatically. The system optimises day-to-day operational activities while ensuring a long-term success perspective for the plant.

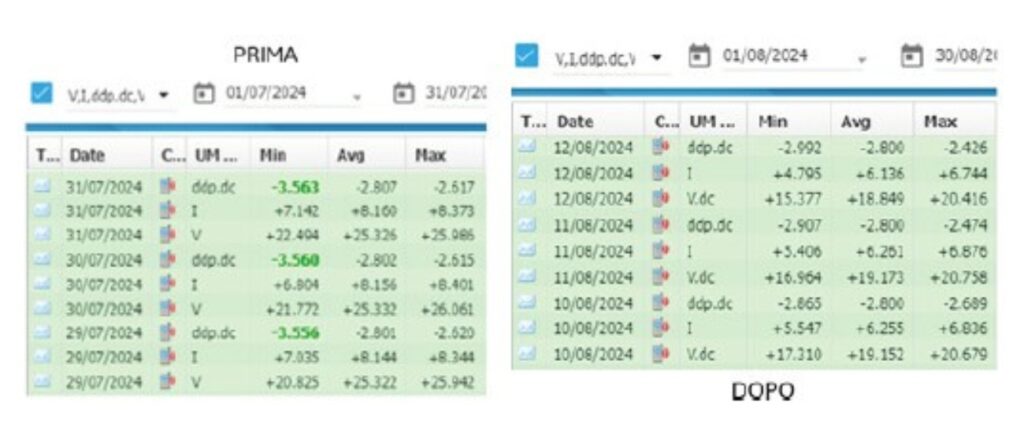

In the presence of a demand for gas from the network, the downtime during which it is not possible to inject biomethane due to fluctuations on the production side is normally around 10 – 12% of the annual hours. Thanks to GOLEM-ZERO, these interruptions decrease by 70 – 80%, allowing for the injection of up to 6 – 8% more biomethane over the course of the year.

Furthermore, unplanned but necessary field balancing interventions to ensure injection priority decrease by up to 35%, which translates into lower operating costs.

AUTOMA designs and produces innovative, Made in Italy hardware and software solutions for remote monitoring and control in the Oil, Gas and Water sectors.

We were born in 1987 in Italy, and today over 50,000 AUTOMA devices are installed in more than 40 countries around the world.

Do you want to ensure a priority and uninterrupted biomethane injection into the network, with maximised uptime?

Contact our team without obligation and we will tell you what we can do to optimise infrastructure operations and control.

Marketing Manager at Automa S.r.l.

Marketing Manager at Automa S.r.l.

As Marketing Manager, Barbara is responsible for defining and managing the strategic communication plan, with a particular focus on product promotion and positioning. She coordinates marketing activities and external collaborations, supports the launch and promotion of the company’s solutions through trade shows, events, and dedicated materials, ensuring consistency and impact of the messages in the market.