Written by Tommaso Russo, Product Manager Area of the AUTOMA Sales Division

From the intervention “A solution for the quantification and reduction of methane emissions”

SMART GRID DAYS 2025, 8 – 9 October 2025.

Monitoring and reducing emissions efficiently are an urgent necessity, not only from an environmental perspective but also from a regulatory one.

Regulation (EU) 2024/1787 marked a turning point for the energy sector. For the first time, the reduction of methane emissions becomes a structured obligation, with precise deadlines and requirements that affect the entire gas supply chain: transport, distribution, storage and regasification.

The regulatory framework, however, is developing in a complex context. The deadlines are tight, the requirements are increasing, and not all of the technical tools supporting the Regulation are fully available yet. Operators are thus faced with having to make operational and investment decisions in an evolving scenario, where regulatory uncertainty is compounded by the practical difficulties of effectively measuring, quantifying and reducing emissions.

It is precisely in this context that a key need emerges: to have solutions that allow us to move from theoretical estimates and sporadic campaigns to continuous and reliable control that can also be used for future compliance purposes.

From detection to emissions management: the limitations of traditional approaches

Today, the search for methane leaks is based mainly on LDAR campaigns carried out with OGI cameras and portable FID detectors. Fundamental tools, but which have structural limitations.

Firstly, the frequency of inspections is limited: the LDAR (Leak Detection and Repair) programme is carried out every three or even six months, and leaks could occur during these intervals.

Another important limitation is human bias: the operator could make mistakes when detecting leaks or may not detect them all. Last but not least, the accessibility of components can also represent a problem: often stations have rather complex configurations and, therefore, components with high leakage rates may not be detected.

Even the quantification of emissions, often based on generic emission factors and inventories that are not always updated, returns an approximate picture, which tends to underestimate actual leaks. This approach may be less and less adequate in the light of new regulatory requirements, which require more representative and verifiable data.

In terms of reduction, available solutions often impose operational compromises: replacement of components with impacts on service continuity, reduction of operating pressure with the risk of not meeting network demand, or difficult or impossible interventions on inaccessible leaks. In the absence of zero-loss components, it becomes apparent that the problem cannot be addressed with a single approach.

MethanEye: monitor and quantify to make better decisions

MethanEye was created with a specific objective: to provide operators with a reliable tool for the continuous monitoring and quantification of methane emissions, transforming a regulatory obligation into an opportunity for control and optimisation.

The device integrates a CH₄ sensor capable of detecting concentrations in ppm and converting them into emissions expressed in kg/year, as required by regulatory requirements. Thanks to its compact design and installation in ATEX zone 0(methane and hydrogen), MethanEye can be placed directly near the source, intercepting even hard-to-reach leaks.

The flexible power supply — from the network, solar panel or battery — allows installations even in remote locations, ensuring almost continuous monitoring (sampling every 30 seconds) or configurable according to operational requirements and the required duration. The result is a constant flow of data, which reduces uncertainty and supports decisions based on real evidence, not on estimates.

MethanEye can easily integrate with existing PLC, G5P Automa and SCADA systems, or operate in stand-alone mode thanks to the integrated modem. This flexibility makes it suitable both for new installations and for the adaptation of existing systems.

Reducing emissions without compromising the network: GOLEM-ZERO

Measuring and quantifying is essential, but not enough. The reduction of emissions also involves a more intelligent management of operating conditions. GOLEM-ZERO was created precisely to meet this need.

It is a smart regulator capable of dynamically regulating network pressure based on real demand conditions, avoiding overpressure phenomena that contribute to increased leaks. Installable in Plug&Play mode, without the need to interrupt the service; the system is applicable to any regulator model and can be easily integrated into existing NTS offtakes and district governors thanks to custom-designed adapters. In addition, GOLEM-ZERO operates thanks to an integrated intelligence system, reducing the need for manual interventions.

Reducing overpressures without compromising service

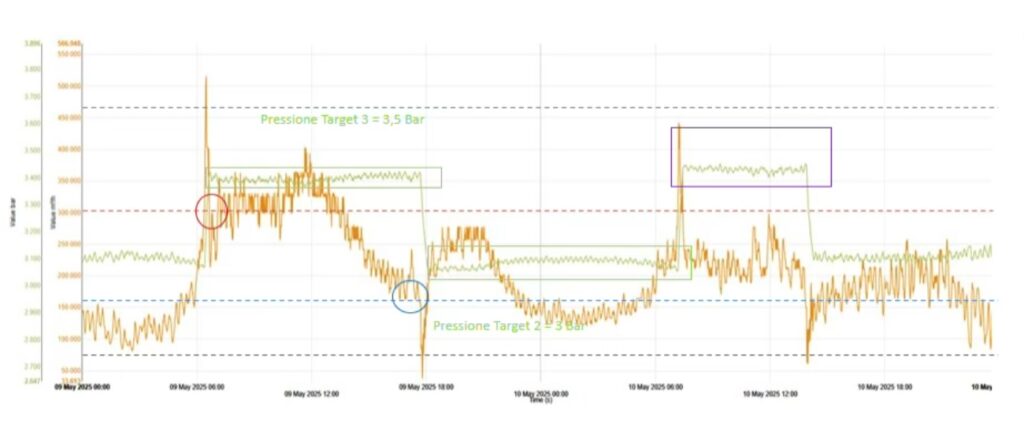

The operating principle of GOLEM-ZERO is based on a flow rate band adjustment. The system divides the network’s operating range into different operating bands, each of which is associated with an optimised target pressure based on demand.

The bands are designed to partially overlap, so as to avoid continuous pressure fluctuations as the flow rate varies. The target pressure is changed only when the flow rate leaves the operating reference band, ensuring operational stability and continuity of service.

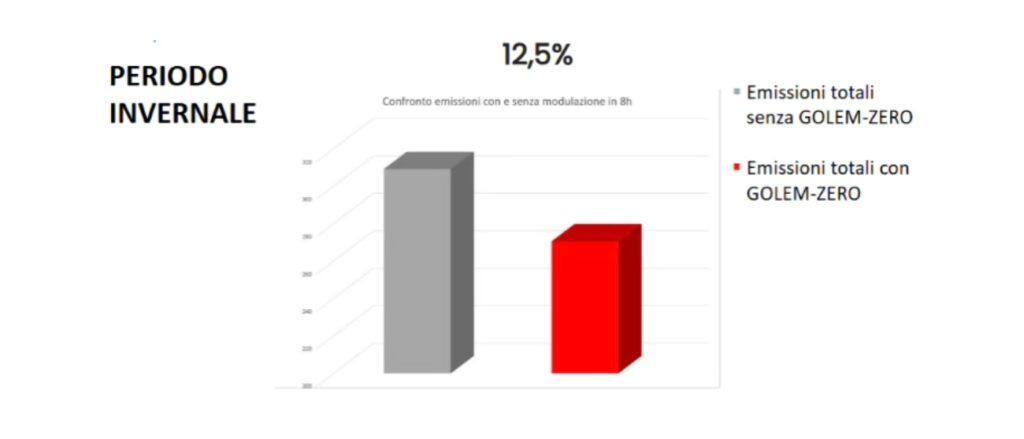

This logic allows GOLEM-ZERO to automatically adapt to different operating conditions — daily, weekly and seasonal — avoiding unnecessary overpressure phenomena. The benefits are also reflected in environmental terms: studies based on models developed by GERG (European Gas Research Group) show reductions in emissions of up to 12.5% in winter and up to 14.5% in summer.

A concrete answer to a real problem

The synergy between MethanEye and GOLEM-ZERO represents a concrete response to the challenges posed by EU Regulation 2024/1787. Not only does it enable methane emissions to be monitored, quantified and reduced, but it also provides operators with a tool to deal with an evolving regulatory environment with greater awareness, reducing operational risk and supporting future compliance.

Product Manager at Automa S.r.l.

Product Manager at Automa S.r.l.

Tommaso Russo is a Junior Product Manager at AUTOMA S.R.L.. With a degree in Electronic Engineering, he explores new market opportunities and proposes solutions in collaboration with the R&D team. He is also actively involved in promoting AUTOMA’s technologies by delivering technical presentations to potential clients and participating in industry events both in Italy and abroad.