European regulations have set the target of zero greenhouse gas emissions, such as methane, by 2050. To comply with these guidelines and therefore achieve the established sustainability goals, it is absolutely necessary to concretely pursue the energy transition objectives using technologically advanced solutions to progressively minimise gas losses in transport and distribution network.Leaks are normal (coming from pipes and joints, for example), but they still have a big impact: just think that we’re talking about leaks that can reach pressures of 4 or even 5 bar for 365 days a year.

Reducing natural gas emissions into the atmosphere and optimising the management of operating pressures in gas networks: this is the clear and ambitious objective, from which the Project 404 was born, which the Automa team is carrying out in synergy with 2i Rete Gas, a company of the Italgas Group.

Launched in 2024 and promoted by the Italian Regulatory Authority for Energy, Networks and Environment (ARERA), Project 404 is part of Resolution 404/2023/R/gas of ARERA, ‘Initiation of a procedure for defining measures aimed at reducing fugitive methane emissions in the natural gas distribution sector’.

In summary, Resolution 404/2023/R/gas aims to:

- Define tools and measures to reduce fugitive methane emissions in natural gas distribution networks;

- Establish monitoring, accounting, and reporting methods for such emissions;

- Promote the adoption of innovative technologies and practices aimed at environmental sustainability and the safety of infrastructures.

The central idea behind Project 404 is strongly innovative and ambitious: to implement the adoption of advanced technologies to dynamically modulate pressure in gas networks, automatically reducing it in real-time during periods of lower consumption.

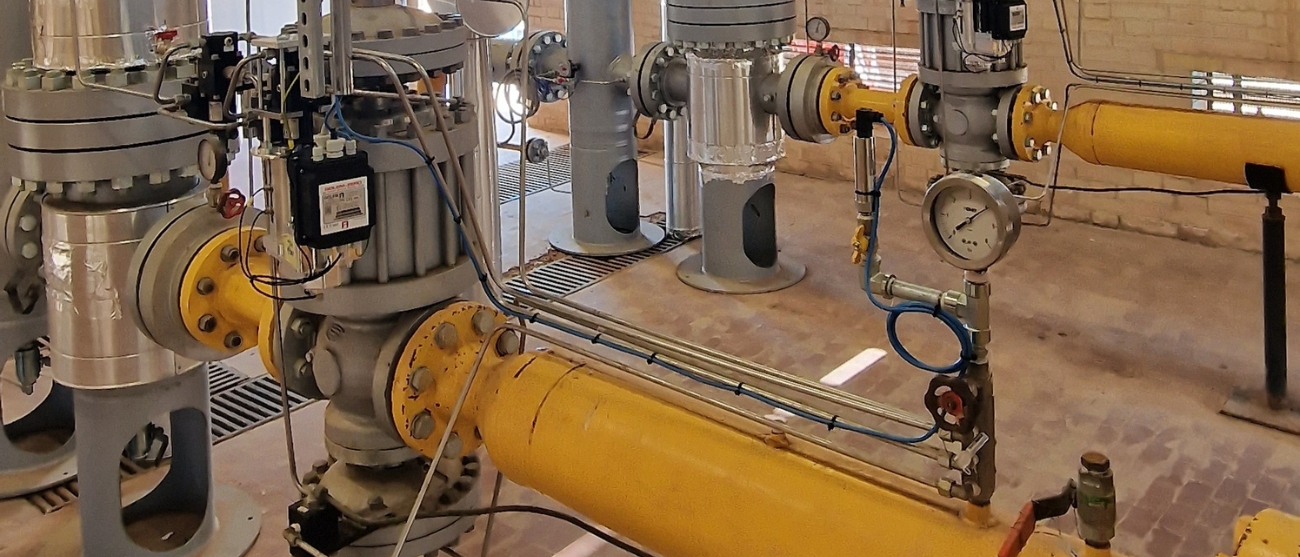

For the implementation of the Project, Automa has employed the GOLEM system, a cutting-edge technological solution for intelligent pressure control.

This application of the GOLEM system introduces an approach to dynamic pressure management that is still little used not only in Italy but also internationally.

The Automa solution: the GOLEM technology applied to pressure control systems on off-take stations.

Automa’s GOLEM system, applied to pressure control systems in off-take stations, revolutionises the traditional static approach to pressure regulation. Unlike conventional methods that maintain a constant pressure based on the maximum annual demand of the plant, GOLEM dynamically modulates pressure based on the actual demand of the network. This allows to reach the highest pressure levels only when actually necessary, significantly lowering the average operating pressure and, consequently, reducing fugitive emissions.

Moreover, it should be noted that the installation of GOLEM is of the Plug&Play type, indeed, it does not require significant interventions on the mechanical and pneumatic part of the system. Meaning that it is not necessary to modify the existing mechanical and pneumatic part of the pressure regulator, it is sufficient to install the GOLEM on the pilot using the specially designed support brackets. The installation process of GOLEM is therefore quick, simple, and low operational impact.

This ease of integration has allowed the adoption of the system within Project 404, where, after an initial phase of laboratory testing, GOLEM has been implemented in the field, demonstrating its effectiveness without compromising service continuity.

The Project provided for the installation of the GOLEM system on a complex configuration represented by 2 interconnected off-take stations serving the same plant.

In this context, the system operates through two algorithms that act in parallel to ensure intelligent and stable management of the stations.

The ultimate goal is the complete automation of the system, with the aid of predictive software capable of anticipating the gas demand of the network.

This will lead to optimal and safe gas distribution management.

How dynamic regulation applied to project 404 works

The uniqueness of the project lies in the ability to make two stations ‘talk’ to each other without the need for any physical connection between them. Indeed, the stations communicate with each other and operate autonomously.

To better understand the operational context, it is useful to distinguish between the different types of off-take stations: the so called ‘antenna’ networks, typically intended to supply confined areas such as a neighbourhood or small municipalities, and those ‘meshed’, integrated into more complex networks, capable of serving larger and more articulated urban areas.

In Project 404, dynamic pressure regulation is implemented on two ‘meshed’ stations, respectively:

- Primary Station: represents the main station that sets and controls the pressure of the network. In meshed networks, there is a Primary Station, while in antenna networks, each station operates as Primary.

- Secondary Station: represents the support station that modulates the gas flow rate delivered based on the parameters detected. In a meshed network, multiple Secondary Stations can coexist.

Both types of stations independently analyse the parameters detected by the network, such as pressure and flow rate, and act independently. Although the two stations follow two different algorithms, both read the same network parameters and this allows them to collaborate and create a single ‘regulation organism’.

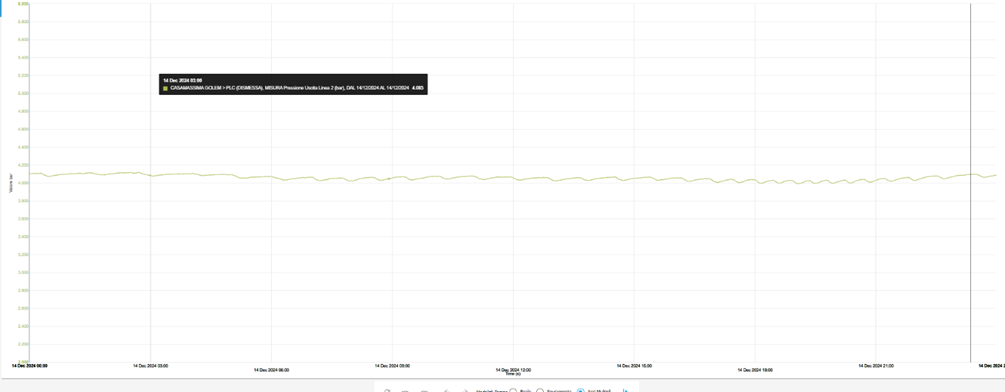

As can be seen from the graph, before installing the Smart Regulator, a static condition occurs. The pressure remains constant, maintaining the level corresponding to the maximum demand of the plant.

Project 404 develops through three main phases:

Phase 1

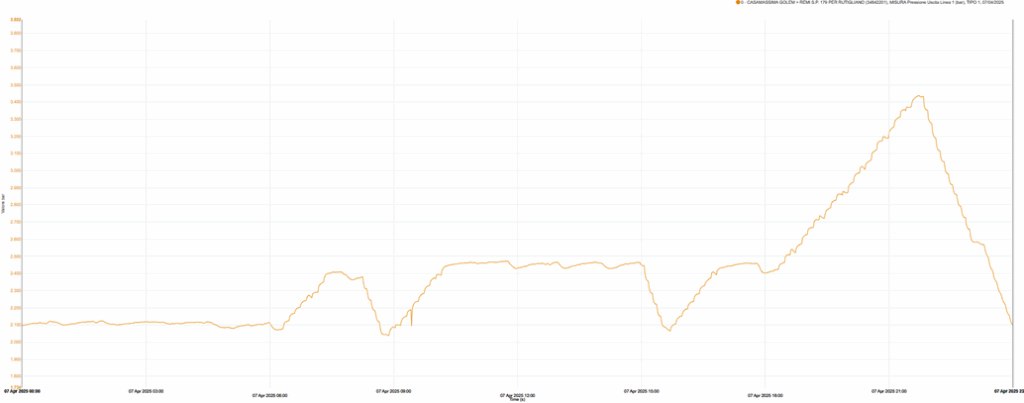

The first phase (already completed) provided for the application of dynamic regulation in defined time slots, modulating the pressure based on the actual gas demand. The aim was to validate the concept of pressure reduction during low consumption periods, such as during the night. The following graph shows the trend of pressure over 24 hours, varying from 4 bar maintained during the day to 2 bar at night.

Phase 2

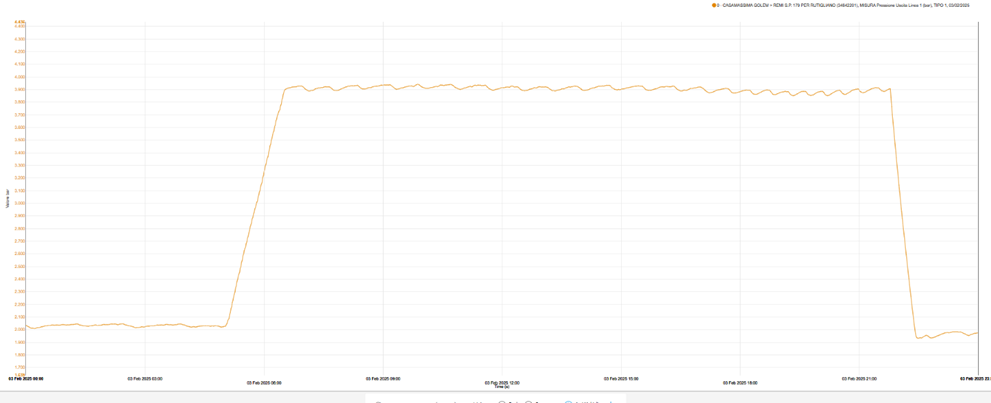

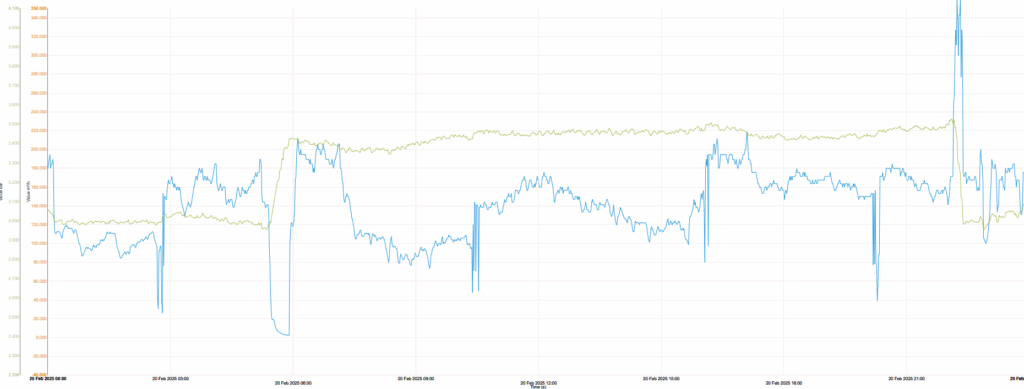

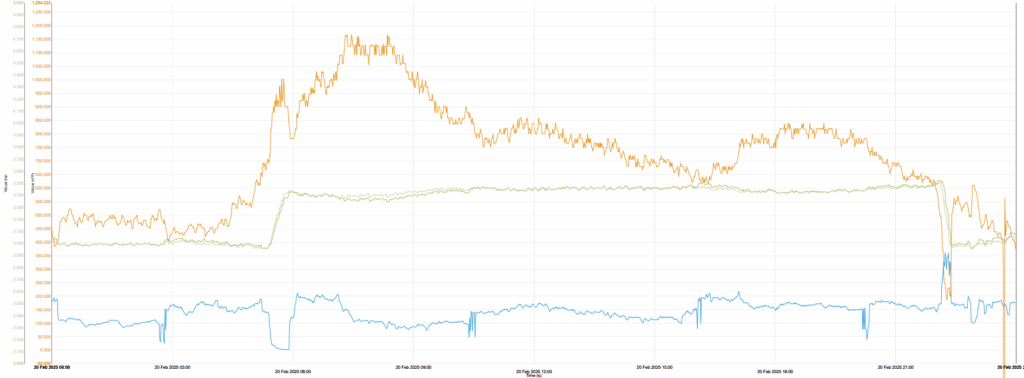

The second phase involves two stations in a meshed network and requires them to be able to operate adapting in real-time to the variations of the network, thanks to an intelligent algorithm capable of responding quickly to different operating conditions. This phase has already been tested and is currently operational in several stations across Italy, demonstrating the reliability and robustness of the solution. The following graph shows how the pressure is maintained between 2 and 2.5 bar for most of the day, only increasing around 8:00 PM, corresponding to the peak demand from users.

A particularly significant element in the operation of the system is the way in which the secondary station, while operating with autonomous control logic, actively contributes to maintaining the overall balance of the network. Its ability to adapt to the pressure set by the primary station and to dynamically modulate the flow rate according to configurable time slots makes it possible to avoid critical situations, such as the reversal of roles between the two stations.

This collaborative behaviour translates into a continuous balance between the flows delivered: when the primary station reduces its contribution, the secondary station increases in a complementary manner, and vice versa. The result is an almost instantaneous response to changes in the network, ensuring system stability and intelligent, distributed flow management.

The following graph clearly shows how the two stations interact: the curve of the secondary station rises exactly when that of the primary station falls, demonstrating effective compensation between the two nodes. An additional graph, showing only the secondary station, allows us to appreciate the specific behaviour of the individual element within the system.

Phase 3

The third phase involves the integration of a predictive algorithm based on artificial intelligence, capable of estimating the demand and flow rate of gas for the following days, further optimising the efficiency of the system.

What can we expect once all three steps of Project 404 are implemented?

To significantly reduce gas losses, actively contributing to the reduction of emissions into the atmosphere. Although the Project is still in the testing phase, the initial results are extremely promising.

With the approval of the competent authorities, this methodology could become a new regulatory standard. Thanks to this innovation, Automa and 2i Rete Gas, a company of the Italgas Group, are charting a path towards a more efficient and sustainable management of gas networks, demonstrating that ecological transition is possible through intelligent and cutting-edge technological solutions.

AUTOMA has been active since 1987 in the development of hardware and software solutions for the remote monitoring and control of gas transport and distribution networks, functional to their operational management. To date, over 50,000 Automa devices are installed in more than 40 countries worldwide.

Do you need to optimise the pressure regulation of gas networks, making it safe and efficient?

Contact our team without obligation and we will tell you how we can intervene.

Project Manager at Automa S.r.l.

Project Manager at Automa S.r.l.

Leonardo Mazzoli is a Junior Project Manager at AUTOMA S.R.L. With a degree in Mechanical Engineering, Leonardo leads product development and market strategy, also overseeing engineering processes. In addition, he supervises research and development projects, fostering technical innovation and the optimization of company solutions.